Volume 7, Issue 2 (June 2022)

J Environ Health Sustain Dev 2022, 7(2): 1684-1697 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Mostofi Sarkari N, Rasoulzadeh Y, Musavi S, Moradi G, Habibi P. Electrospun Polyurethane/β-Cyclodextrin Composite Membranes for Aerosol Filtration and Adsorption of Volatile Organic Compounds from the Air. J Environ Health Sustain Dev 2022; 7 (2) :1684-1697

URL: http://jehsd.ssu.ac.ir/article-1-423-en.html

URL: http://jehsd.ssu.ac.ir/article-1-423-en.html

Department of Occupational Health Engineering, School of Health, Tabriz University of Medical Sciences, Tabriz, Iran.

Full-Text [PDF 981 kb]

(317 Downloads)

| Abstract (HTML) (786 Views)

.PNG)

Figure 1: (a) Preparation of PU sample, (b) PU solution preparation, and (c) PU/β-cyclodextrin solution preparation

.PNG)

Figure 2: Electrospinning of nanofiber membrane

.PNG)

Figure 3: Measurement of filtration parameters in fabricated nanofibers

.PNG)

Statistical method

After collecting the data and entering to SPSS26, a regression test with the stepwise method was used to diagnose the relation between toluene adsorption and β-CD concentration.

Ethical issues

This research was completed in accordance with the ethical principles of, and was approved by, the research ethics committee of Tabriz University of Medical Sciences (IR.TBZMED.VCR.REC.1399. 373).

Results

FTIR analysis

Figure 5 represents the results of FTIR spectroscopy. According to the spectra, spectroscopy of PTMG and the final PU mixture was carried out before and after curing. The elimination of isocyanate bonding characteristic (N=C=O) at a wavenumber of 2235 cm-1, as well as wavenumbers of 3227 and 3400 cm-1, besides formation of –NH at a wavenumber of 3300 cm-1, improved the reaction of PU.

Investigation of morphological characteristics of nanofiber membranes

Figure 6 reveals the SEM images of pure PU nanofiber and composite nanofibers, which were contained different amounts of β-CD. The diameter distribution is shown for each type of nanofiber. The electrospun pure PU nanofiber had a uniform and bead-free structure with an average diameter of 796 nm, while β-CD-containing nanofibrous membranes compared to pure PU membrane had smaller fiber diameters. The nanofiber membrane containing 3 wt% β-CD had the smallest diameter size (average diameter: 153 nm). According to the Figure 6, the morphology of PU/5 wt% β-CD was nonuniform and electrospun nanofiber diameter size increased at this concentration of β-CD.

.PNG)

Figure 5: FTIR spectrum of PTMG and synthesized PU (before and after curing)

.PNG)

Figure 6: SEM images, morphology (column a), and diameter size distribution (column b) of different electrospun nanofiber membranes

Air filtration

Figure 7 shows the filtration efficiency of various types of β-CD electrospun nanofiber membranes against DOP particles at a mean diameter size of 300 nm and 5 cm/s face velocity. According to the results of this figure, PU/3 wt% of β-CD nanofiber had the highest filtration efficiency (97.1%).

.PNG)

Figure 7: Percentage of filtration efficiency in composite nanofiber membranes

.PNG)

Figure 8: Pressure drop in composite nanofiber membranes

.PNG)

Figure 9: Quality factor in composite nanofiber membranes

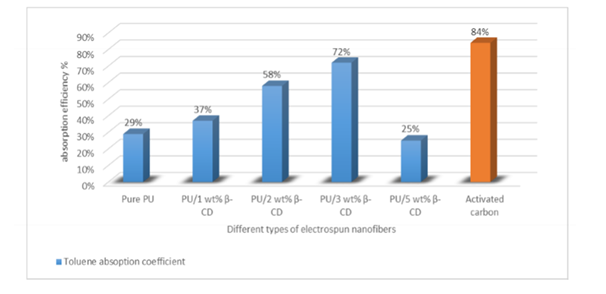

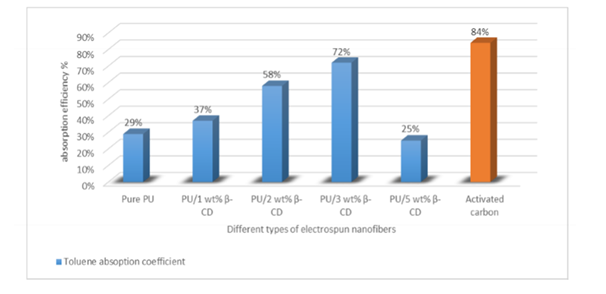

Figure 10: Toluene adsorption capacity of electrospun nanofibers and AC

Full-Text: (288 Views)

Electrospun Polyurethane/β-Cyclodextrin Composite Membranes for Aerosol Filtration and Adsorption of Volatile Organic Compounds from the Air

Nasim Mostofi Sarkari 1, Yahya Rasoulzadeh 1, Saeed Musavi 2, Gholamreza Moradi 1*, Peymaneh Habibi 3

1 Department of Occupational Health Engineering, School of Health, Tabriz University of Medical Sciences, Tabriz, Iran.

2 Department of Biostatistics and Epidemiology, Faculty of Health, Tabriz University of Medical Sciences, Tabriz, Iran.

3 Department of Occupational Health Engineering, School of Public Health, Tehran University of Medical Sciences, Tehran, Iran.

Nasim Mostofi Sarkari 1, Yahya Rasoulzadeh 1, Saeed Musavi 2, Gholamreza Moradi 1*, Peymaneh Habibi 3

1 Department of Occupational Health Engineering, School of Health, Tabriz University of Medical Sciences, Tabriz, Iran.

2 Department of Biostatistics and Epidemiology, Faculty of Health, Tabriz University of Medical Sciences, Tabriz, Iran.

3 Department of Occupational Health Engineering, School of Public Health, Tehran University of Medical Sciences, Tehran, Iran.

| A R T I C L E I N F O | ABSTRACT | |

| ORIGINAL ARTICLE | Introduction: Electrospun nanomembranes have been used for effective air filtration due to their potential for active surface modification. This study aims to synthesize polyurethane (PU) nanofiber membrane incorporated with different amounts of β-cyclodextrin (β-CD) to capture volatile organic compounds (VOCs) along with aerosol filtration from the air. Material and Methods: First, PU was synthesized by MDI method. A 10 wt% PU solution in DMF/MEK (1:1 wt) was prepared. Various amounts of β-CD powder (0, 1, 2, 3, and 5 wt% of PU) were dispersed in the prepared PU solution. Electrospining process was carried out under determined parameters (20 kV applied voltage, tip-to-collector distance of 10 cm, solution feed, and rate of 1 ml/h). The chemical structure and morphology of the produced samples were assessed by FTIR and SEM, respectively. Finally, air filtration and toluene adsorption of different electrospun membranes were measured. Results: The highest filtration performance was observed for PU with 1 wt% β-CD nanofiber. Due to increased efficiency (83.13%) and low-pressure drop (∆P = 19 pa), this sample had a considerable quality parameter. The results demonstrated that the membrane loaded with β-CD was able to adsorb hazardous and carcinogenic VOCs. It was confirmed that adding β-CD into PU improves the adsorption capacity due to forming a π complex and having a different tendency against capturing a variety of VOCs. Conclusion: The study results revealed that the PU nanofiber incorporated with β-CD, along with the ease of regeneration, can make them attractive for air filtration and VOCs adsorption. |

|

Article History: Received: 12 March 2022 Accepted: 20 April 2022 |

||

*Corresponding Author: Gholamreza Moradi Email: moradig@tbzmed.ac.ir Tel: +984133357582 |

||

Keywords: Nanofibers, Volatile Organic Compounds, Adsorption, Air Pollutants, Filtration. |

Citation: Mostofi Sarkari N, Rasoulzadeh Y, Musavi S, et al. Electrospun Polyurethane/β-Cyclodextrin Composite Membranes for Aerosol Filtration and Adsorption of Volatile Organic Compounds from the Air. J Environ Health Sustain Dev. 2022; 7(2): 1684-97.

Introduction

Air pollution is a global issue threatening human lives and the environment1,2. Classification of air pollutants which ranges from suspended particles to gaseous versus particulate pollutants, recognizing and applying appropriate methods and equipment to decrease or eliminate contaminants. Particulate matter (PM) refers to solid and liquid particles suspended in the air with various sizes and compositions emitted from different sources3. Man-made activities, such as industrial processes, vehicle emissions, and even indoor activities can cause the emission of aerosol and volatile organic compounds (VOCs). PM are classified into 3 groups, including

VOCs are an expanded spectrum of organic compounds with a boiling point of 50-260 ℃ at atmospheric pressure. Due to lower boiling temperatures, evaporations rapidly spread out in indoor and outdoor space. Therefore, they have been considered as the most important air contaminant 8. People working in areas in contact with VOCs, are significantly exposed to the compounds through inhalation 9. The adverse effects of VOCs cause skin irritation, respiratory problems, and cancer (in case of long-term exposure) 10. Purification of breathing air at indoor exposures is one of the important issues. Filtration is one of the most considerable mechanisms of purifying the air from different types of contaminants 11. Many air filtration materials have been developed, such as glass fiber 12, activated carbon (AC) fiber 13 (which is considered to be one of the best air purification materials due to its unique features), nanometer fiber 14, and film compound filter materials 15. Non-woven fibers have been identified as efficient absorbents in nanometer-scale due to the smaller diameters, high surface area and porosity, low weight, and good internal connectivity 16-18. Electrospinning is a simple and cost-effective approach that leads to the fabrication of non-woven nanofiber membranes. It is also known as an efficient approach for synthesizing fiber membranes with high-performance air filter application 19,20. A set of common polymers commercially have been used in the electrospinning process, such as PAN 21,22 , Poly (L-lactic) acid 23, polyurethane (PU) 24, and cellulose acetate 25. Among these, electrospun PU membranes have been extensively known for their good elasticity and mechanical strength 26.

Since pure polymeric electrospun nanofibers without modification have very low adsorption capacities of gases, an additional step of treatment is required for their acceptable performance. In most cases, the incorporation of nanoparticles into a polymeric solution results in constrictive modifications in nanofiber’s morphology and diameter characteristics, which leads to the generation of high-efficiency filter membranes. Kim et al. demonstrated that the PU electrospun nanofiber mat incorporated with fly ash nanoparticles has a significant adsorption capacity against VOCs compared to pure PU nanofiber mat 27. Cyclodextrins are a family of cyclic oligosaccharides with a hydrophobic interior and hydrophilic exterior, in which the glucopyranose units are joined by α-1, 4 bonds. Among different types of cyclodextrin, β-cyclodextrin (β-CD) (as a commercially biological supermolecule 28) has the advantages of being non-toxic, cost-effective, and most available compared to other cyclodextrins 29,30. In its chemical structure, seven glucose units have surrounded the hydrophobic cavity 31-33. One of the noticeable characteristics of β-CD is the formation of complex properties with many other components 34,35. β-CD (host) cavities provide a connection ring shape location for non-polar and suitable guest molecules, which end up in complex formation 36. The most appropriate guest components which are accepted by β-CD as host include alcohols, aldehydes, ketones, fatty acids, other organic acids, gases, and also VOCs, such as styrene, aniline, and toluene as well as formaldehyde 37. Among expanded applications of this electrospun membrane, filtration of breathing air against any fine particles and toxic gases and vapors is another unique application of these membranes. Cartridges of common protective respiratory masks are packed with AC granolas, which adsorb contaminants. Despite nanofiber high surface area and excellent adsorption, the considerable weight of the cartridge part due to presence of AC, applies excessive load and stress to neck muscles, leading to uncomforted condition for user. Therefore, replacement of conventional filter cartridges by low-weight electrospun nanofibers with adequate efficiency can be a good solution.

Herein, PU was synthesized based on PTMG and MDI. Then, β-CD-incorporated PU composite nanofibers were fabricated using electrospinning process. The physico-chemical characteristics of nanofibers were analyzed by appropriate tools. Finally, simultaneous air filtration and VOC adsorption of the pure PU and β-CD/PU nanofibers were measured.

Materials and Methods

Polytetetramethylene ether glycol (PTMG) with

4- Methylene diphenyl diisocyanate (MDI) was purchased from Sigma Aldrich (USA). The utilized liquids were dibutyltin dilaurate, Β-cyclodextrin, dimethylformamide, dry toluene, dibutylamine, isopropyl alcohol, bromophenol blue, ethyl methyl ketone, HCl 0.01 N, and dried tetrahydrofuran, all supplied by Merck Co. (Germany).

Preparation of PU samples

First of all, dehumidification of PTMG and 1, 4-butanediol was carried out through a vacuum oven at 70 ºC for 3 h and 40 ºC for 1h, respectively. DMF was distilled under the 200 mbar vacuum at 105 ºC. A certain amount of distilled MDI (69.2 mmol) was mixed with 200 ml of dried tetrahydrofuran solvent, and under the dry nitrogen flow, it was purged into a certain amount of PTMG alcohol (13.8 mmol) and 0.1 ml of dibutyltin dilaurate. Then, the mixture was heated (Figure 1 (a)) 38.

Calculation of reaction progress

The reaction progress evaluation was carried out by ASTM D2572 standard test method. 1.1 mEq of NCO was transferred into 250 cc Erlenmeyer and 25 cc toluene was added. The mixture was stirred for 20 min while it was covered by a lid. 25 cc of dibutyl amine 0.1 N was added into the mixture and again stirred for 15 min with a closed lid. Then, 100 cc of isopropyl alcohol and 4-6 drops of bromophenol blue marker were introduced. Finally, it was tittered by HCL 0.01 N. These steps were carried out for a blank sample. The reaction was carried out until the theoretical isocyanate content determined by di-n-butyl amine titration was reached. % NCO was calculated by Equation 1 38.

% NCO =× N ×0.042 W ×100

In which, and

and  indicates the volume of HCL for titration of blank (cc) and volume of HCL for titration of the sample (cc), respectively. Also, N and W show the normality of HCL and grams of the sample weight (gr). The constant number 0.042 refers to the miliequivalent weight of the NCO group.

indicates the volume of HCL for titration of blank (cc) and volume of HCL for titration of the sample (cc), respectively. Also, N and W show the normality of HCL and grams of the sample weight (gr). The constant number 0.042 refers to the miliequivalent weight of the NCO group.

Solution preparation

A 10 wt% PU solution in DMF/MEK (1:1 wt) was prepared using a magnetic stirrer with 300 rpm for 12 h at ambient temperature (Figure 1(b)). Various amounts of β-CD powder (0, 1, 2, 3, and 5 wt% of PU) were dispersed by ultrasonication for 15 min to attain a homogenous solution (Figure 1(c)).

Electrospinning

The electrospinning setup (Figure 2) was comprised of three main parts, including a high voltage power supply, a syringe pump, and a ground electrode collector. The employed electrospinning parameters were 20 kV applied voltage, tip-to-collector distance of 10 cm, solution feed rate of 1 ml/h, and collector rotation rate of 300 rpm. Nanofibers with varied densities were prepared by changing the electrospinning duration. After electrospinning, all membranes were dried in a vacuum oven for 4 h at 50 ºC.

Air pollution is a global issue threatening human lives and the environment1,2. Classification of air pollutants which ranges from suspended particles to gaseous versus particulate pollutants, recognizing and applying appropriate methods and equipment to decrease or eliminate contaminants. Particulate matter (PM) refers to solid and liquid particles suspended in the air with various sizes and compositions emitted from different sources3. Man-made activities, such as industrial processes, vehicle emissions, and even indoor activities can cause the emission of aerosol and volatile organic compounds (VOCs). PM are classified into 3 groups, including

VOCs are an expanded spectrum of organic compounds with a boiling point of 50-260 ℃ at atmospheric pressure. Due to lower boiling temperatures, evaporations rapidly spread out in indoor and outdoor space. Therefore, they have been considered as the most important air contaminant 8. People working in areas in contact with VOCs, are significantly exposed to the compounds through inhalation 9. The adverse effects of VOCs cause skin irritation, respiratory problems, and cancer (in case of long-term exposure) 10. Purification of breathing air at indoor exposures is one of the important issues. Filtration is one of the most considerable mechanisms of purifying the air from different types of contaminants 11. Many air filtration materials have been developed, such as glass fiber 12, activated carbon (AC) fiber 13 (which is considered to be one of the best air purification materials due to its unique features), nanometer fiber 14, and film compound filter materials 15. Non-woven fibers have been identified as efficient absorbents in nanometer-scale due to the smaller diameters, high surface area and porosity, low weight, and good internal connectivity 16-18. Electrospinning is a simple and cost-effective approach that leads to the fabrication of non-woven nanofiber membranes. It is also known as an efficient approach for synthesizing fiber membranes with high-performance air filter application 19,20. A set of common polymers commercially have been used in the electrospinning process, such as PAN 21,22 , Poly (L-lactic) acid 23, polyurethane (PU) 24, and cellulose acetate 25. Among these, electrospun PU membranes have been extensively known for their good elasticity and mechanical strength 26.

Since pure polymeric electrospun nanofibers without modification have very low adsorption capacities of gases, an additional step of treatment is required for their acceptable performance. In most cases, the incorporation of nanoparticles into a polymeric solution results in constrictive modifications in nanofiber’s morphology and diameter characteristics, which leads to the generation of high-efficiency filter membranes. Kim et al. demonstrated that the PU electrospun nanofiber mat incorporated with fly ash nanoparticles has a significant adsorption capacity against VOCs compared to pure PU nanofiber mat 27. Cyclodextrins are a family of cyclic oligosaccharides with a hydrophobic interior and hydrophilic exterior, in which the glucopyranose units are joined by α-1, 4 bonds. Among different types of cyclodextrin, β-cyclodextrin (β-CD) (as a commercially biological supermolecule 28) has the advantages of being non-toxic, cost-effective, and most available compared to other cyclodextrins 29,30. In its chemical structure, seven glucose units have surrounded the hydrophobic cavity 31-33. One of the noticeable characteristics of β-CD is the formation of complex properties with many other components 34,35. β-CD (host) cavities provide a connection ring shape location for non-polar and suitable guest molecules, which end up in complex formation 36. The most appropriate guest components which are accepted by β-CD as host include alcohols, aldehydes, ketones, fatty acids, other organic acids, gases, and also VOCs, such as styrene, aniline, and toluene as well as formaldehyde 37. Among expanded applications of this electrospun membrane, filtration of breathing air against any fine particles and toxic gases and vapors is another unique application of these membranes. Cartridges of common protective respiratory masks are packed with AC granolas, which adsorb contaminants. Despite nanofiber high surface area and excellent adsorption, the considerable weight of the cartridge part due to presence of AC, applies excessive load and stress to neck muscles, leading to uncomforted condition for user. Therefore, replacement of conventional filter cartridges by low-weight electrospun nanofibers with adequate efficiency can be a good solution.

Herein, PU was synthesized based on PTMG and MDI. Then, β-CD-incorporated PU composite nanofibers were fabricated using electrospinning process. The physico-chemical characteristics of nanofibers were analyzed by appropriate tools. Finally, simultaneous air filtration and VOC adsorption of the pure PU and β-CD/PU nanofibers were measured.

Materials and Methods

Polytetetramethylene ether glycol (PTMG) with

4- Methylene diphenyl diisocyanate (MDI) was purchased from Sigma Aldrich (USA). The utilized liquids were dibutyltin dilaurate, Β-cyclodextrin, dimethylformamide, dry toluene, dibutylamine, isopropyl alcohol, bromophenol blue, ethyl methyl ketone, HCl 0.01 N, and dried tetrahydrofuran, all supplied by Merck Co. (Germany).

Preparation of PU samples

First of all, dehumidification of PTMG and 1, 4-butanediol was carried out through a vacuum oven at 70 ºC for 3 h and 40 ºC for 1h, respectively. DMF was distilled under the 200 mbar vacuum at 105 ºC. A certain amount of distilled MDI (69.2 mmol) was mixed with 200 ml of dried tetrahydrofuran solvent, and under the dry nitrogen flow, it was purged into a certain amount of PTMG alcohol (13.8 mmol) and 0.1 ml of dibutyltin dilaurate. Then, the mixture was heated (Figure 1 (a)) 38.

Calculation of reaction progress

The reaction progress evaluation was carried out by ASTM D2572 standard test method. 1.1 mEq of NCO was transferred into 250 cc Erlenmeyer and 25 cc toluene was added. The mixture was stirred for 20 min while it was covered by a lid. 25 cc of dibutyl amine 0.1 N was added into the mixture and again stirred for 15 min with a closed lid. Then, 100 cc of isopropyl alcohol and 4-6 drops of bromophenol blue marker were introduced. Finally, it was tittered by HCL 0.01 N. These steps were carried out for a blank sample. The reaction was carried out until the theoretical isocyanate content determined by di-n-butyl amine titration was reached. % NCO was calculated by Equation 1 38.

% NCO =

In which,

and

and  indicates the volume of HCL for titration of blank (cc) and volume of HCL for titration of the sample (cc), respectively. Also, N and W show the normality of HCL and grams of the sample weight (gr). The constant number 0.042 refers to the miliequivalent weight of the NCO group.

indicates the volume of HCL for titration of blank (cc) and volume of HCL for titration of the sample (cc), respectively. Also, N and W show the normality of HCL and grams of the sample weight (gr). The constant number 0.042 refers to the miliequivalent weight of the NCO group.Solution preparation

A 10 wt% PU solution in DMF/MEK (1:1 wt) was prepared using a magnetic stirrer with 300 rpm for 12 h at ambient temperature (Figure 1(b)). Various amounts of β-CD powder (0, 1, 2, 3, and 5 wt% of PU) were dispersed by ultrasonication for 15 min to attain a homogenous solution (Figure 1(c)).

Electrospinning

The electrospinning setup (Figure 2) was comprised of three main parts, including a high voltage power supply, a syringe pump, and a ground electrode collector. The employed electrospinning parameters were 20 kV applied voltage, tip-to-collector distance of 10 cm, solution feed rate of 1 ml/h, and collector rotation rate of 300 rpm. Nanofibers with varied densities were prepared by changing the electrospinning duration. After electrospinning, all membranes were dried in a vacuum oven for 4 h at 50 ºC.

.PNG)

Figure 1: (a) Preparation of PU sample, (b) PU solution preparation, and (c) PU/β-cyclodextrin solution preparation

.PNG)

Figure 2: Electrospinning of nanofiber membrane

Characterization of electrospun nanofibers

The Fourier-transform infrared spectroscopy (FTIR) spectra of samples were recorded using an Equinox 55 spectrometer (Bruker, Germany). The spectra were collected in 400-4000 cm-1 wavenumber range with 4 cm-1 spectral resolution. The surface morphology and nanofibers’ diameters were investigated by scanning electron microscopy (SEM). The employed equipment was VEGA 2 SEM (Tescan, Czechia), and the micrographs were captured with 15.00 kV acceleration voltage.

Air filtration

The oil mist method was used to investigate the air filtration performance parameters of electrospun nanofiber membranes. This testing system consists of a pump, rotameter, ULPA filter, dust generator, filter holder, dust counter, and manometer (Figure 3). Each type of membrane individually was placed in a filter holder. At the beginning of the test, internal airflow into the setup was purified by passing through a ULPA filter. Monodisperse dioctyl phthalate (DOP) particles with a diameter size of 300 nm were generated through an electrospray mechanism by a dust generator (ESP-3480 TSI) which was located before the filter holder. In this study, due to the importance of the size of exposed particles from the point of view of health and technology, the size of particles was considered 300 nm. This equipment generated aerosol with a concentration of10 7

E = n in - n out n in

In Equation 2, E refers to filtration efficiency,n in n out

∆ P = P in - P out

In Equation 3,∆ P P in P out

Q = - (1- E )

In Equation 4,Q  refers to quality factor parameter.

refers to quality factor parameter.

The Fourier-transform infrared spectroscopy (FTIR) spectra of samples were recorded using an Equinox 55 spectrometer (Bruker, Germany). The spectra were collected in 400-4000 cm-1 wavenumber range with 4 cm-1 spectral resolution. The surface morphology and nanofibers’ diameters were investigated by scanning electron microscopy (SEM). The employed equipment was VEGA 2 SEM (Tescan, Czechia), and the micrographs were captured with 15.00 kV acceleration voltage.

Air filtration

The oil mist method was used to investigate the air filtration performance parameters of electrospun nanofiber membranes. This testing system consists of a pump, rotameter, ULPA filter, dust generator, filter holder, dust counter, and manometer (Figure 3). Each type of membrane individually was placed in a filter holder. At the beginning of the test, internal airflow into the setup was purified by passing through a ULPA filter. Monodisperse dioctyl phthalate (DOP) particles with a diameter size of 300 nm were generated through an electrospray mechanism by a dust generator (ESP-3480 TSI) which was located before the filter holder. In this study, due to the importance of the size of exposed particles from the point of view of health and technology, the size of particles was considered 300 nm. This equipment generated aerosol with a concentration of

In Equation 2, E refers to filtration efficiency,

In Equation 3,

In Equation 4,

refers to quality factor parameter.

refers to quality factor parameter..PNG)

Figure 3: Measurement of filtration parameters in fabricated nanofibers

Toluene adsorption efficiency test

For the toluene adsorption experiment, pure and hybrid electrospun PU membranes with a surface area of 19.62

For the toluene adsorption experiment, pure and hybrid electrospun PU membranes with a surface area of 19.62

.PNG)

Figure 4: (a): Measurement of adsorption efficiency of fabricated nanofiber membranes, (b): membrane holder (left), and cross-sectional view of the holder with electrospun membrane (right)

Statistical method

After collecting the data and entering to SPSS26, a regression test with the stepwise method was used to diagnose the relation between toluene adsorption and β-CD concentration.

Ethical issues

This research was completed in accordance with the ethical principles of, and was approved by, the research ethics committee of Tabriz University of Medical Sciences (IR.TBZMED.VCR.REC.1399. 373).

Results

FTIR analysis

Figure 5 represents the results of FTIR spectroscopy. According to the spectra, spectroscopy of PTMG and the final PU mixture was carried out before and after curing. The elimination of isocyanate bonding characteristic (N=C=O) at a wavenumber of 2235 cm-1, as well as wavenumbers of 3227 and 3400 cm-1, besides formation of –NH at a wavenumber of 3300 cm-1, improved the reaction of PU.

Investigation of morphological characteristics of nanofiber membranes

Figure 6 reveals the SEM images of pure PU nanofiber and composite nanofibers, which were contained different amounts of β-CD. The diameter distribution is shown for each type of nanofiber. The electrospun pure PU nanofiber had a uniform and bead-free structure with an average diameter of 796 nm, while β-CD-containing nanofibrous membranes compared to pure PU membrane had smaller fiber diameters. The nanofiber membrane containing 3 wt% β-CD had the smallest diameter size (average diameter: 153 nm). According to the Figure 6, the morphology of PU/5 wt% β-CD was nonuniform and electrospun nanofiber diameter size increased at this concentration of β-CD.

.PNG)

Figure 5: FTIR spectrum of PTMG and synthesized PU (before and after curing)

.PNG)

Figure 6: SEM images, morphology (column a), and diameter size distribution (column b) of different electrospun nanofiber membranes

Air filtration

Figure 7 shows the filtration efficiency of various types of β-CD electrospun nanofiber membranes against DOP particles at a mean diameter size of 300 nm and 5 cm/s face velocity. According to the results of this figure, PU/3 wt% of β-CD nanofiber had the highest filtration efficiency (97.1%).

.PNG)

Figure 7: Percentage of filtration efficiency in composite nanofiber membranes

Figure 8 indicates the pressure drop parameter in different electrospun nanofibers for 0.3 µm particles at a face velocity of 5 cm.s-1. PU/1 wt% of β-CD had the lower pressure drop. This parameter increased by increasing the amount of β-CD, , in which the PU/2 wt% of β-CD membrane had the highest pressure drop.

.PNG)

Figure 8: Pressure drop in composite nanofiber membranes

Figure 9 presents the quality factor of different types of nanofiber membranes for 0.3 µm particles at a face velocity of 5 cm.s-1. Among different electrospun nanofiber membranes, PU/1 wt% of β-CD had the higest QF. This parameter decreased by increasing the amount of β-CD membranes,

in which PU/2 wt% of β-CD had lowest

QF.

in which PU/2 wt% of β-CD had lowest

QF.

.PNG)

Figure 9: Quality factor in composite nanofiber membranes

Figure 10 demonstrates toluene adsorption capacity of different electrospun nanofiber membranes. Based on the results, the adsorption capacity of pure PU membrane increased by adding β-CD nanoparticles. This adsorption trend increased by adding the 3 wt% of β-CD into pure PU nanofiber, but increasing the concentration up to 5 wt% of β-CD had the reverse response. Figure 10 represents the adsorption capacity of AC, besides electrospun nanofibers. The capacity of PU/ 3 wt% β-CD and AC for toluene vapor was estimated at 72% and 84%, respectively.

Figure 10: Toluene adsorption capacity of electrospun nanofibers and AC

In this study, a statistical regression model was drawn to determine the relationship between toluene adsorption and β-CD concentration and also to specify the optimal concentration of β-CD. The regression equation is the output of modeling as shown in Equation 5:

Adsorption =22.7+31.2( β - CD )-6.03 ( β - CD ) 2

The coefficient of determination was 85.88% for the model. In other words, 85.88% of the variation in adsorption was defined by β-CD and (β-CD)2 in the model. According to the model, the maximum adsorption (62.94%) was obtained at a β-CD concentration of 2.58%.

Discussion

FTIR spectroscopy was carried out to confirm the formation of PU by poly (tetramethylene ether) glycol (PTMG) as the soft segment, 1,4-butanediol (BDO) as the chain extender, and methylene diphenyl diisocyanate (MDI) as the hard segment. Similar results have been reported in the literature analyzing synthesized PU spectroscopy 39,40. The quantitative and qualitative results of nanofiber morphological analysis were recorded with SEM images. An important feature of electrospinning is that the morphology and diameter of nanofibers are changeable based on the electrospinning parameters 41. The polymer concentration, flow rate, and voltage are the most critical factors that affect the morphology of nanofiber membranes 42. By increasing the amount of β-CD in the electrospun solution, the mean diameter of β-CD nanofibers became smaller compared to pure PU nanofibers. It can be due to the grown conductivity and viscosity of PU/β-CD solution; a similar result has been reported by Kim et al 43. Moreover, increasing the β-CD concentration up to the optimal level produced uniform and bead-free nanofibers. Therefore, increasing the β-CD concentration up to 3 wt% provided an effective nanofiber membrane. Increasing β-CD component into an electrospun solution up to 5 wt% caused the fabrication of non-uniform nanofibers with larger diameter. It was due to a significant difference in electrospinning solution viscosity.

Filtration is an important method for separating aerosols from the air by passing through the porous membrane 44. In this approach, suspended particles, that are durable on the fiber of membrane by Vander valance links, are predominately captured by mechanisms, such as diffusion, inertial impaction, and direct impaction 45. The performance of the filter is described by filtration parameters, which include collection efficiency and pressure drop. Figure 7 reveals the highest filtration efficiency (97.1%) in PU/3 wt% of β-CD nanofiber, which was correlated with the smallest fiber diameters. Nanofibers also showed lower efficiency (92.63%) compared to PU/3 wt% β-CD nanofiber (97.1%) for 0.3 µm particles, as observed in SEM micrographs (Figure 6). This reduction was attributed to the thicker fiber diameter of PU/5 wt% β-CD versus 3 wt% β-CD. By increasing the β-CD content, the pressure drop increased noticeably in the samples from 19 Ps for 1 wt% β-CD to 33 Pa for 5 wt% at an air velocity of 5 cm/s. On the other hand, the pressure drop trend was almost similar for samples containing 1 wt% to 3 wt% β-CD. Slight fluctuations were observed in the pressure drop, increasing from 26 Pa for 3 wt% β-CD to 33 Pa for 5 wt% β-CD samples. The increase in pressure drop could be attributed to the increase in fiber diameter (Figure 6), pore size, and irregular structure as a consequence of the β-CD presence in the composite PU incorporated with 5 wt% β-CD nanofiber.

Quality factor (QF) can be used as an indicator to measure the filtration performance of fibrous filters, also known as the figure of merit, which is the ratio of the penetration rate of particles to pressure drop across the filter 46. QF is a function of filtration efficiency and pressure drop, which reflects the cost-benefit principle, where the cost refers to pressure drop (a cause of significant energy consumption) 47 and benefit refers to filtration efficiency. As a practical role, an excellent filter should provide maximum filtration efficiency and minimum pressure drop. Nanofibers with significant QF show high quality and performance. 1 wt% β-CD nanofiber membranes, due to their lower pressure drop and desirable filtration efficiency, had a significant QF. Generally, air filters with higher filtration efficiencies because of the smaller pore size are more easily blocked 48. Although the PU incorporated with 5 wt% β-CD membrane had a rather higher filtration efficiency, the increased pressure drop was the cause of lower QF owing to less porosity.

The mechanism of filter purification against particles and gas contaminants is completely different. In other words, a particle is captured upon interception with a nonwoven fiber owing to its large aerodynamic diameter and high inertia. Meanwhile, a gaseous contaminant can pass through the porosity of non-treated nonwoven fiber due to its smaller size and lower inertia. Therefore, to enhance the performance of nanofiber membranes, these nanomembranes should be embedded with substances, such as nanoparticles that can adsorb unfavorable gases and vapors. The adsorption performance of a PU nanofiber is strongly related to parameters, such as the morphology of pore and diameter of polymer, which change depending on the content of additives. Importantly, when the diameters of polymer fiber materials decrease from micrometers to sub-microns or nanometers, several surprising characteristics arise. They include a very large surface-area-to-volume ratio, flexibility in surface functionality, and superior mechanical performance to other known materials. Therefore, improved adsorption/ desorption performance is expected from electrospun nanofibers due to their small diameter and high porosity.

Toluene is an aromatic hydrocarbon, composed of a benzene ring linked to one methyl group. It has been used as a solvent or a chemical intermediate in various industrial applications. As shown in Figure 10, an increase in the β-CD content leads to an increase in the adsorption capacity of composites. Except for the sample containing 5wt% β-CD, the adsorption efficiency of all composite nanofibers was higher than the pure PU nanofiber membrane. The highest adsorption efficiency was obtained when 3 wt % β-CD was combined with PU nanofiber. As can be seen in Figure 10, samples containing more β-CD showed a higher adsorption capacity in the composites. Therefore, the adsorption capacity depends on several important parameters, including β-CD content, pore morphology, and diameter of polymer. Overall, these parameters determine the final adsorption capacity of the composite.

According to Figure 10, PU/3 wt% β-CD shows the highest adsorption efficiency among all membranes tested. By adding 3 wt% β-CD, toluene adsorption further improved by 72%, which can be attributed to the cavities of β-CD trapping toluene. However, the addition of 5 wt% β-CD did not improve toluene adsorption. Adsorption is dramatically improved when β-CD is added to nanofibers, leading to a decrease in the fiber diameter and an increase in the specific surface area. If the adsorption efficiency is determined per surface, it changes by adding β-CD, which may be due to variations in pore morphology and polymer diameter. Samples with weight percentages of 3 wt% and 5 wt% exhibited the maximum and minimum adsorption efficiencies, respectively. Therefore, optimal adsorption efficiency was obtained at a weight percentage of 3 wt%, indicating the efficacy of β-CD as a candidate for adsorption of pollutants. Decreased adsorption efficiency after adding 3 wt% to 5 wt% can be attributed to higher polymer matrix viscosity, causing stiffness and mass formation. A previous study demonstrated that the membrane cross-linked with β-CD powder could adsorb hazardous and carcinogenic VOCs, such as xylene, benzene, and formaldehyde 49. Also, Kadam et al. reported that the adsorption of HCOH through β-CD powder was higher than PAN powder. Significant adsorption was reported in the electrospun PAN/ β-CD membrane due to thin fiber diameter, large surface area, and high affinity of β-CD to form a complex 50.

It can be concluded that β-CD absorbs toluene via two mechanisms. The cone-shaped β-CD contains a hydrophobic cavity with a specific diameter and depth 51. In the first approach, according to the structure of β-CD, the formation of the π complex occurs in the β-CD cavity (host) to capture toluene as a guest molecule. In the other adsorption mechanism, toluene is captured by bonding OH groups, which surround the exterior structure of β-CD cavity. Overall, increasing the concentration of β-CD up to an optimal level in the nanofiber membrane enhances toluene adsorption. This nanoparticle shows different tendencies to capture a variety of VOCs.

The capacity of PU/ 3 wt% β-CD and AC for toluene vapor was estimated at 72% and 84%, respectively. Moreover, it was observed that PU/ 3 wt% β-CD nanofiber membranes (0.22 g) had acceptable efficiency for capturing toluene vapor in comparison with the AC absorbent (0.46 g). Therefore, the synthesized multilayer nanofiber can be an appropriate substitute for the AC adsorbents because of lower pressure drop, large surface, and lower weight.

Conclusion

Herein, PU/ β-CD nanofiber membranes were fabricated via the electrospinning process for air filtration and toluene adsorption. Adding β-CD to the PU solution produced nanofibers with different morphological characteristics. The thinner diameter and the thicker diameter contained 3 Wt% and 5 Wt% of β-CD, respectively. Among five electrospun membranes, the highest QF was obtained for PU/1 wt % β-CD membrane. This membrane could capture particles with a 300 nm diameter owing to its lower pressure drop (19 Pa) and acceptable filtration efficiency (83.13%), which was important in terms of health and technology.

The results of this study also showed that the nanofiber membrane containing 3 wt% β-CD had the highest adsorption efficiency of toluene. In this type of membrane, β-CD adsorbs toluene by forming a host-gest complex. According to the statistical regression model, the maximum toluene adsorption (62.94%) was obtained when the β-CD concentration was 2.58%. Moreover, it was found that PU/3 wt% β-CD nanofiber membrane had acceptable efficiency to capture toluene vapors compared to the AC absorbent. Therefore, multilayer synthesized composite nanofibers, due to less pressure drop and efficient adsorption capacity could be an appropriate option substitute for AC. According to the findings, synthesized PU/ β-CD nanofiber media, due to significant efficiency to capture toxic evaporations of VOCs and particle filtration, can be an appropriate and practical option for people who are exposed to indoor or outdoor aerosol and gaseous contaminants, such as hospital personnel, traffic police, and patients with respiratory disorders.

Acknowledgements

This study has been supported by Tabriz University of Medical Sciences grant number 66239. The authors are grateful to Tabriz University of Medical Sciences, Tabriz, Iran, for supporting the study.

Funding

This study was done without receiving funding.

Conflicts of interest

The authors declare that there is no conflict of interest.

This is an Open-Access article distributed in accordance with the terms of the Creative Commons Attribution (CC BY 4.0) license, which permits others to distribute, remix, adapt, and build upon this work for commercial use.

Reference

1. Zarei F, Azari MR, Salehpour S, et al. Respiratory effects of simultaneous exposure to respirable crystalline silica dust, formaldehyde, and triethylamine of a group of foundry workers. J Res Health sci. 2017;17(1):371

2. Sadighzadeh A, Mohammadpour H, Omidi L, et al . Application of acoustic agglomeration for removing sulfuric acid mist from air stream. Sustainable Environment Research. 2018;28(1): 20-4.

3. Fiordelisi A, Piscitelli P, Trimarco B, et al. The mechanisms of air pollution and particulate matter in cardiovascular diseases. Heart Fail Rev. 2017;22(3):337-47.

4. Bernstein JA, Alexis N, Barnes C, et al. Health effects of air pollution. J Allergy Clin Immunol. 2004;114(5):1116-23.

5. Martinelli N, Olivieri O, Girelli D. Air particulate matter and cardiovascular disease: a narrative review. Eur J Intern Med. 2013;24(4): 295-302.

6. De Hartog J, Hoek G, Peters A, et al. Effects of fine and ultrafine particles on cardiorespiratory symptoms in elderly subjects with coronary heart disease: the ULTRA study. Am J Epidemiol. 2003;157(7):613-23.

7. Zhu M, Han J, Wang F, et al. Electrospun nanofibers membranes for effective air filtration. Macromol Mater Eng. 2017;302(1):1600353.

8. Fenske JD, Paulson SE. Human breath emissions of VOCs. J Air Waste Manag Assoc. 1999;49(5):594-8.

9. Rumchev K, Brown H, Spickett J. Volatile organic compounds: do they present a risk to our health?. Rev Environ Health. 2007;22(1):39.

10. Jones AP. Indoor air quality and health. Atmospheric environment. 1999;33(28):4535-64.

11. Sutherland KS, Chase G. Filters and filtration handbook: Elsevier; 2011.

12. Zou C, Shi Y, Qian X. Characterization of glass fiber felt and its performance as an air filtration media. Journal of Industrial Textiles. 2020.

13. Bandosz TJ. Activated carbon surfaces in environmental remediation: Elsevier; 2006.

14. Wang H, Yang ZY, Liu JY, et al. Research on the advantages of nanofibrous air filtration membrane. Key Eng Mater. 2011:474-476:2016-19.

15. Yang C-F, Tian D, He JH. Preparation of a Cu-Btc/Pan electrospun film with a good air performance. Thermal Science. 2021;25:1469-75.

16. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

17. Fan Zy, Zhao Yl, Zhu Xy, et al. Folic acid modified electrospun poly (vinyl alcohol)/ polyethyleneimine nanofibers for cancer cell capture applications. Npj Mater Degrad. 2016;34(6):755-65.

18. Lu P, Ding B. Applications of electrospun fibers. Recent Pat Nanotechnol. 2008;2(3):169-82.

19. Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28(3):325-47.

20. Moradi G, Sedighzadeh A, Yarahmadi R, et al. Synthesis of nano-fibrous mats using electrospinning method and determining their efficiency for nanoaerososls removal. Int J Occup Environ Med. 2014;11(4):1-11.

21. Yun KM, Hogan CJ, Matsubayashi Y, et al. Nanoparticle filtration by electrospun polymer fibers. Chem Eng Sci. 2007;62(17):4751-9.

22. Dehghan SF, Golbabaei F, Maddah B, et al. Optimization of electrospinning parameters for polyacrylonitrile-MgO nanofibers applied in air filtration. J Air Waste Manag Assoc. 2016;66(9): 912-21.

23. Maleki H, Semnani Rahbar R, Saadatmand MM, et al. Physical and morphological characterisation of poly (L-lactide) acid-based electrospun fibrous structures: Tunning solution properties. Plastics, Rubber and Composites. 2018;47(10):438-46.

24. Erdem R, Usta İ, Akalin M, et al. The impact of solvent type and mixing ratios of solvents on the properties of polyurethane based electrospun nanofibers. Appl Surf Sci. 2015;334:227-30.

25. Khoshnevisan K, Maleki H, Samadian H, et al. Cellulose acetate electrospun nanofibers for drug delivery systems: Applications and recent advances. Carbohydr Polym. 2018;198:131-41.

26. Poudyal A, Beckermann GW, Chand NA, et al. Electrospun Nanofibre Filter Media: New Emergent Technologies and Market Perspectives. Filtering Media by Electrospinning: Springer; 2018. p. 197-224.

27. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

28. Kadam V, Kyratzis IL, Truong YB, et al. Air filter media functionalized with β‐Cyclodextrin for efficient adsorption of volatile organic compounds. J Appl Polym Sci. 2020;137(40): 49228.

29. Voncina B, Le Marechal AM. Grafting of cotton with β‐cyclodextrin via poly (carboxylic acid). J appl polym sci. 2005;96(4):1323-8.

30. Liu Y, Li J. Advances of cyclodextrin polymers for the delivery of biotech drugs. Journal of Bioresources and Bioproducts. 2016;1(1):7-17.

31. Jansook P, Ogawa N, Loftsson T. Cyclodextrins: structure, physicochemical properties and pharmaceutical applications. Int J Pharm. 2018;535(1-2):272-84.

32. Wenz G. Cyclodextrins as building blocks for supramolecular structures and functional units. Angew Chem Int Ed Engl. 1994;33(8):803-22.

33. Periasamy R. A systematic review on the significant roles of cyclodextrins in the construction of supramolecular systems and their potential usage in various fields. J Carbohydr Chem. 2020:39:189-216.

34. Shimpi S, Chauhan B, Shimpi P. Cyclodextrins: application in different routes of drug administration. Acta Pharm. 2005;55(2):139-56.

35. Sharma N, Baldi A. Exploring versatile applications of cyclodextrins: an overview. Drug Deliv. 2016;23(3):729-47.

36. Periasamy R, Kothainayaki S, Sivakumar K. Investigation on inter molecular complexation between 4, 4′-methylene-bis (N, N-dimethylaniline) and β-cyclodextrin: Preparation and characterization in aqueous medium and solid state. J Mol Struct. 2015;1080: 69-79.

37. Schmid G. Cyclodextrin glycosyltransferase production: yield enhancement by overexpression of cloned genes. Trends Biotechnol. 1989;7(9):244-8.

38. Honarkar H, Barmar M, Barikani M. Synthesis, characterization and properties of waterborne polyurethanes based on two different ionic centers. Fibers and Polymers. 2015;16(4):718-25.

39. Moradi G, Nassiri P, Ershad-Langroudi A, et al. Acoustical, damping and thermal properties of polyurethane/poly (methyl methacrylate)-based semi-interpenetrating polymer network foams. Plastics, Rubber and Composites. 2018;47(5):221-31.

40. Tang Q, Gao K. Structure analysis of polyether-based thermoplastic polyurethane elastomers by FTIR, 1H NMR and 13C NMR. International Journal of Polymer Analysis and Characterization. 2017;22(7):569-74.

41. Wu H, Pan W, Lin D, et al. Electrospinning of ceramic nanofibers: Fabrication, assembly and applications. Journal of Advanced Ceramics. 2012;1(1):2-23.

42. Noreña-Caro D, Alvarez-Láinez M. Experimental design as a tool for the manufacturing of filtering media based on electrospun polyacrylonitrile/β-cyclodextrin fibers. International Journal on Interactive Design and Manufacturing. 2016;10(2):153-64.

43. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

44. Dehghan SF, Golbabaei F, Maddah B, et al. Optimization of electrospinning parameters for polyacrylonitrile-MgO nanofibers applied in air filtration. J Air Waste Manag Assoc. 2016;66(9): 912-21.

45. Moradi GR, Sadighzadeh A, Yarahmadi R, et al. Investigating the collection efficiency of ulpa filters for the removal of nano-sized aerosols. Iran Occupational Health. 2013:10(2):1-10.

46. Shou D, Fan J. Structural optimization of porous media for fast and controlled capillary flows. Physical Review E. 2015;91(5):053021.

47. Fisk WJ, Faulkner D. Performance and cost of particle air filtration technologies. Indoor Air. 2001;12:223-34.

48. Li P, Wang C, Zhang Y, et al. Air filtration in the free molecular flow regime: a review of high‐efficiency particulate air filters based on carbon nanotubes. Small. 2014;10(22):4543-61.

49. Kadam V, Kyratzis IL, Truong YB, et al. Air filter media functionalized with β‐Cyclodextrin for efficient adsorption of volatile organic compounds. J Appl Polym Sci. 2020;137(40): 49228.

50. Kadam V, Truong YB, Easton C, et al. Electrospun Polyacrylonitrile/β-Cyclodextrin composite membranes for simultaneous air filtration and adsorption of volatile organic compounds. ACS Appl Nano Mater. 2018;1(8):4268-77.

51. Ciobanu A, Landy D, Fourmentin S. Complexation efficiency of cyclodextrins for volatile flavor compounds. Int Food Res. 2013;53(1):110-4.

The coefficient of determination was 85.88% for the model. In other words, 85.88% of the variation in adsorption was defined by β-CD and (β-CD)2 in the model. According to the model, the maximum adsorption (62.94%) was obtained at a β-CD concentration of 2.58%.

Discussion

FTIR spectroscopy was carried out to confirm the formation of PU by poly (tetramethylene ether) glycol (PTMG) as the soft segment, 1,4-butanediol (BDO) as the chain extender, and methylene diphenyl diisocyanate (MDI) as the hard segment. Similar results have been reported in the literature analyzing synthesized PU spectroscopy 39,40. The quantitative and qualitative results of nanofiber morphological analysis were recorded with SEM images. An important feature of electrospinning is that the morphology and diameter of nanofibers are changeable based on the electrospinning parameters 41. The polymer concentration, flow rate, and voltage are the most critical factors that affect the morphology of nanofiber membranes 42. By increasing the amount of β-CD in the electrospun solution, the mean diameter of β-CD nanofibers became smaller compared to pure PU nanofibers. It can be due to the grown conductivity and viscosity of PU/β-CD solution; a similar result has been reported by Kim et al 43. Moreover, increasing the β-CD concentration up to the optimal level produced uniform and bead-free nanofibers. Therefore, increasing the β-CD concentration up to 3 wt% provided an effective nanofiber membrane. Increasing β-CD component into an electrospun solution up to 5 wt% caused the fabrication of non-uniform nanofibers with larger diameter. It was due to a significant difference in electrospinning solution viscosity.

Filtration is an important method for separating aerosols from the air by passing through the porous membrane 44. In this approach, suspended particles, that are durable on the fiber of membrane by Vander valance links, are predominately captured by mechanisms, such as diffusion, inertial impaction, and direct impaction 45. The performance of the filter is described by filtration parameters, which include collection efficiency and pressure drop. Figure 7 reveals the highest filtration efficiency (97.1%) in PU/3 wt% of β-CD nanofiber, which was correlated with the smallest fiber diameters. Nanofibers also showed lower efficiency (92.63%) compared to PU/3 wt% β-CD nanofiber (97.1%) for 0.3 µm particles, as observed in SEM micrographs (Figure 6). This reduction was attributed to the thicker fiber diameter of PU/5 wt% β-CD versus 3 wt% β-CD. By increasing the β-CD content, the pressure drop increased noticeably in the samples from 19 Ps for 1 wt% β-CD to 33 Pa for 5 wt% at an air velocity of 5 cm/s. On the other hand, the pressure drop trend was almost similar for samples containing 1 wt% to 3 wt% β-CD. Slight fluctuations were observed in the pressure drop, increasing from 26 Pa for 3 wt% β-CD to 33 Pa for 5 wt% β-CD samples. The increase in pressure drop could be attributed to the increase in fiber diameter (Figure 6), pore size, and irregular structure as a consequence of the β-CD presence in the composite PU incorporated with 5 wt% β-CD nanofiber.

Quality factor (QF) can be used as an indicator to measure the filtration performance of fibrous filters, also known as the figure of merit, which is the ratio of the penetration rate of particles to pressure drop across the filter 46. QF is a function of filtration efficiency and pressure drop, which reflects the cost-benefit principle, where the cost refers to pressure drop (a cause of significant energy consumption) 47 and benefit refers to filtration efficiency. As a practical role, an excellent filter should provide maximum filtration efficiency and minimum pressure drop. Nanofibers with significant QF show high quality and performance. 1 wt% β-CD nanofiber membranes, due to their lower pressure drop and desirable filtration efficiency, had a significant QF. Generally, air filters with higher filtration efficiencies because of the smaller pore size are more easily blocked 48. Although the PU incorporated with 5 wt% β-CD membrane had a rather higher filtration efficiency, the increased pressure drop was the cause of lower QF owing to less porosity.

The mechanism of filter purification against particles and gas contaminants is completely different. In other words, a particle is captured upon interception with a nonwoven fiber owing to its large aerodynamic diameter and high inertia. Meanwhile, a gaseous contaminant can pass through the porosity of non-treated nonwoven fiber due to its smaller size and lower inertia. Therefore, to enhance the performance of nanofiber membranes, these nanomembranes should be embedded with substances, such as nanoparticles that can adsorb unfavorable gases and vapors. The adsorption performance of a PU nanofiber is strongly related to parameters, such as the morphology of pore and diameter of polymer, which change depending on the content of additives. Importantly, when the diameters of polymer fiber materials decrease from micrometers to sub-microns or nanometers, several surprising characteristics arise. They include a very large surface-area-to-volume ratio, flexibility in surface functionality, and superior mechanical performance to other known materials. Therefore, improved adsorption/ desorption performance is expected from electrospun nanofibers due to their small diameter and high porosity.

Toluene is an aromatic hydrocarbon, composed of a benzene ring linked to one methyl group. It has been used as a solvent or a chemical intermediate in various industrial applications. As shown in Figure 10, an increase in the β-CD content leads to an increase in the adsorption capacity of composites. Except for the sample containing 5wt% β-CD, the adsorption efficiency of all composite nanofibers was higher than the pure PU nanofiber membrane. The highest adsorption efficiency was obtained when 3 wt % β-CD was combined with PU nanofiber. As can be seen in Figure 10, samples containing more β-CD showed a higher adsorption capacity in the composites. Therefore, the adsorption capacity depends on several important parameters, including β-CD content, pore morphology, and diameter of polymer. Overall, these parameters determine the final adsorption capacity of the composite.

According to Figure 10, PU/3 wt% β-CD shows the highest adsorption efficiency among all membranes tested. By adding 3 wt% β-CD, toluene adsorption further improved by 72%, which can be attributed to the cavities of β-CD trapping toluene. However, the addition of 5 wt% β-CD did not improve toluene adsorption. Adsorption is dramatically improved when β-CD is added to nanofibers, leading to a decrease in the fiber diameter and an increase in the specific surface area. If the adsorption efficiency is determined per surface, it changes by adding β-CD, which may be due to variations in pore morphology and polymer diameter. Samples with weight percentages of 3 wt% and 5 wt% exhibited the maximum and minimum adsorption efficiencies, respectively. Therefore, optimal adsorption efficiency was obtained at a weight percentage of 3 wt%, indicating the efficacy of β-CD as a candidate for adsorption of pollutants. Decreased adsorption efficiency after adding 3 wt% to 5 wt% can be attributed to higher polymer matrix viscosity, causing stiffness and mass formation. A previous study demonstrated that the membrane cross-linked with β-CD powder could adsorb hazardous and carcinogenic VOCs, such as xylene, benzene, and formaldehyde 49. Also, Kadam et al. reported that the adsorption of HCOH through β-CD powder was higher than PAN powder. Significant adsorption was reported in the electrospun PAN/ β-CD membrane due to thin fiber diameter, large surface area, and high affinity of β-CD to form a complex 50.

It can be concluded that β-CD absorbs toluene via two mechanisms. The cone-shaped β-CD contains a hydrophobic cavity with a specific diameter and depth 51. In the first approach, according to the structure of β-CD, the formation of the π complex occurs in the β-CD cavity (host) to capture toluene as a guest molecule. In the other adsorption mechanism, toluene is captured by bonding OH groups, which surround the exterior structure of β-CD cavity. Overall, increasing the concentration of β-CD up to an optimal level in the nanofiber membrane enhances toluene adsorption. This nanoparticle shows different tendencies to capture a variety of VOCs.

The capacity of PU/ 3 wt% β-CD and AC for toluene vapor was estimated at 72% and 84%, respectively. Moreover, it was observed that PU/ 3 wt% β-CD nanofiber membranes (0.22 g) had acceptable efficiency for capturing toluene vapor in comparison with the AC absorbent (0.46 g). Therefore, the synthesized multilayer nanofiber can be an appropriate substitute for the AC adsorbents because of lower pressure drop, large surface, and lower weight.

Conclusion

Herein, PU/ β-CD nanofiber membranes were fabricated via the electrospinning process for air filtration and toluene adsorption. Adding β-CD to the PU solution produced nanofibers with different morphological characteristics. The thinner diameter and the thicker diameter contained 3 Wt% and 5 Wt% of β-CD, respectively. Among five electrospun membranes, the highest QF was obtained for PU/1 wt % β-CD membrane. This membrane could capture particles with a 300 nm diameter owing to its lower pressure drop (19 Pa) and acceptable filtration efficiency (83.13%), which was important in terms of health and technology.

The results of this study also showed that the nanofiber membrane containing 3 wt% β-CD had the highest adsorption efficiency of toluene. In this type of membrane, β-CD adsorbs toluene by forming a host-gest complex. According to the statistical regression model, the maximum toluene adsorption (62.94%) was obtained when the β-CD concentration was 2.58%. Moreover, it was found that PU/3 wt% β-CD nanofiber membrane had acceptable efficiency to capture toluene vapors compared to the AC absorbent. Therefore, multilayer synthesized composite nanofibers, due to less pressure drop and efficient adsorption capacity could be an appropriate option substitute for AC. According to the findings, synthesized PU/ β-CD nanofiber media, due to significant efficiency to capture toxic evaporations of VOCs and particle filtration, can be an appropriate and practical option for people who are exposed to indoor or outdoor aerosol and gaseous contaminants, such as hospital personnel, traffic police, and patients with respiratory disorders.

Acknowledgements

This study has been supported by Tabriz University of Medical Sciences grant number 66239. The authors are grateful to Tabriz University of Medical Sciences, Tabriz, Iran, for supporting the study.

Funding

This study was done without receiving funding.

Conflicts of interest

The authors declare that there is no conflict of interest.

This is an Open-Access article distributed in accordance with the terms of the Creative Commons Attribution (CC BY 4.0) license, which permits others to distribute, remix, adapt, and build upon this work for commercial use.

Reference

1. Zarei F, Azari MR, Salehpour S, et al. Respiratory effects of simultaneous exposure to respirable crystalline silica dust, formaldehyde, and triethylamine of a group of foundry workers. J Res Health sci. 2017;17(1):371

2. Sadighzadeh A, Mohammadpour H, Omidi L, et al . Application of acoustic agglomeration for removing sulfuric acid mist from air stream. Sustainable Environment Research. 2018;28(1): 20-4.

3. Fiordelisi A, Piscitelli P, Trimarco B, et al. The mechanisms of air pollution and particulate matter in cardiovascular diseases. Heart Fail Rev. 2017;22(3):337-47.

4. Bernstein JA, Alexis N, Barnes C, et al. Health effects of air pollution. J Allergy Clin Immunol. 2004;114(5):1116-23.

5. Martinelli N, Olivieri O, Girelli D. Air particulate matter and cardiovascular disease: a narrative review. Eur J Intern Med. 2013;24(4): 295-302.

6. De Hartog J, Hoek G, Peters A, et al. Effects of fine and ultrafine particles on cardiorespiratory symptoms in elderly subjects with coronary heart disease: the ULTRA study. Am J Epidemiol. 2003;157(7):613-23.

7. Zhu M, Han J, Wang F, et al. Electrospun nanofibers membranes for effective air filtration. Macromol Mater Eng. 2017;302(1):1600353.

8. Fenske JD, Paulson SE. Human breath emissions of VOCs. J Air Waste Manag Assoc. 1999;49(5):594-8.

9. Rumchev K, Brown H, Spickett J. Volatile organic compounds: do they present a risk to our health?. Rev Environ Health. 2007;22(1):39.

10. Jones AP. Indoor air quality and health. Atmospheric environment. 1999;33(28):4535-64.

11. Sutherland KS, Chase G. Filters and filtration handbook: Elsevier; 2011.

12. Zou C, Shi Y, Qian X. Characterization of glass fiber felt and its performance as an air filtration media. Journal of Industrial Textiles. 2020.

13. Bandosz TJ. Activated carbon surfaces in environmental remediation: Elsevier; 2006.

14. Wang H, Yang ZY, Liu JY, et al. Research on the advantages of nanofibrous air filtration membrane. Key Eng Mater. 2011:474-476:2016-19.

15. Yang C-F, Tian D, He JH. Preparation of a Cu-Btc/Pan electrospun film with a good air performance. Thermal Science. 2021;25:1469-75.

16. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

17. Fan Zy, Zhao Yl, Zhu Xy, et al. Folic acid modified electrospun poly (vinyl alcohol)/ polyethyleneimine nanofibers for cancer cell capture applications. Npj Mater Degrad. 2016;34(6):755-65.

18. Lu P, Ding B. Applications of electrospun fibers. Recent Pat Nanotechnol. 2008;2(3):169-82.

19. Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28(3):325-47.

20. Moradi G, Sedighzadeh A, Yarahmadi R, et al. Synthesis of nano-fibrous mats using electrospinning method and determining their efficiency for nanoaerososls removal. Int J Occup Environ Med. 2014;11(4):1-11.

21. Yun KM, Hogan CJ, Matsubayashi Y, et al. Nanoparticle filtration by electrospun polymer fibers. Chem Eng Sci. 2007;62(17):4751-9.

22. Dehghan SF, Golbabaei F, Maddah B, et al. Optimization of electrospinning parameters for polyacrylonitrile-MgO nanofibers applied in air filtration. J Air Waste Manag Assoc. 2016;66(9): 912-21.

23. Maleki H, Semnani Rahbar R, Saadatmand MM, et al. Physical and morphological characterisation of poly (L-lactide) acid-based electrospun fibrous structures: Tunning solution properties. Plastics, Rubber and Composites. 2018;47(10):438-46.

24. Erdem R, Usta İ, Akalin M, et al. The impact of solvent type and mixing ratios of solvents on the properties of polyurethane based electrospun nanofibers. Appl Surf Sci. 2015;334:227-30.

25. Khoshnevisan K, Maleki H, Samadian H, et al. Cellulose acetate electrospun nanofibers for drug delivery systems: Applications and recent advances. Carbohydr Polym. 2018;198:131-41.

26. Poudyal A, Beckermann GW, Chand NA, et al. Electrospun Nanofibre Filter Media: New Emergent Technologies and Market Perspectives. Filtering Media by Electrospinning: Springer; 2018. p. 197-224.

27. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

28. Kadam V, Kyratzis IL, Truong YB, et al. Air filter media functionalized with β‐Cyclodextrin for efficient adsorption of volatile organic compounds. J Appl Polym Sci. 2020;137(40): 49228.

29. Voncina B, Le Marechal AM. Grafting of cotton with β‐cyclodextrin via poly (carboxylic acid). J appl polym sci. 2005;96(4):1323-8.

30. Liu Y, Li J. Advances of cyclodextrin polymers for the delivery of biotech drugs. Journal of Bioresources and Bioproducts. 2016;1(1):7-17.

31. Jansook P, Ogawa N, Loftsson T. Cyclodextrins: structure, physicochemical properties and pharmaceutical applications. Int J Pharm. 2018;535(1-2):272-84.

32. Wenz G. Cyclodextrins as building blocks for supramolecular structures and functional units. Angew Chem Int Ed Engl. 1994;33(8):803-22.

33. Periasamy R. A systematic review on the significant roles of cyclodextrins in the construction of supramolecular systems and their potential usage in various fields. J Carbohydr Chem. 2020:39:189-216.

34. Shimpi S, Chauhan B, Shimpi P. Cyclodextrins: application in different routes of drug administration. Acta Pharm. 2005;55(2):139-56.

35. Sharma N, Baldi A. Exploring versatile applications of cyclodextrins: an overview. Drug Deliv. 2016;23(3):729-47.

36. Periasamy R, Kothainayaki S, Sivakumar K. Investigation on inter molecular complexation between 4, 4′-methylene-bis (N, N-dimethylaniline) and β-cyclodextrin: Preparation and characterization in aqueous medium and solid state. J Mol Struct. 2015;1080: 69-79.

37. Schmid G. Cyclodextrin glycosyltransferase production: yield enhancement by overexpression of cloned genes. Trends Biotechnol. 1989;7(9):244-8.

38. Honarkar H, Barmar M, Barikani M. Synthesis, characterization and properties of waterborne polyurethanes based on two different ionic centers. Fibers and Polymers. 2015;16(4):718-25.

39. Moradi G, Nassiri P, Ershad-Langroudi A, et al. Acoustical, damping and thermal properties of polyurethane/poly (methyl methacrylate)-based semi-interpenetrating polymer network foams. Plastics, Rubber and Composites. 2018;47(5):221-31.

40. Tang Q, Gao K. Structure analysis of polyether-based thermoplastic polyurethane elastomers by FTIR, 1H NMR and 13C NMR. International Journal of Polymer Analysis and Characterization. 2017;22(7):569-74.

41. Wu H, Pan W, Lin D, et al. Electrospinning of ceramic nanofibers: Fabrication, assembly and applications. Journal of Advanced Ceramics. 2012;1(1):2-23.

42. Noreña-Caro D, Alvarez-Láinez M. Experimental design as a tool for the manufacturing of filtering media based on electrospun polyacrylonitrile/β-cyclodextrin fibers. International Journal on Interactive Design and Manufacturing. 2016;10(2):153-64.

43. Kim HJ, Pant HR, Choi NJ, et al. Composite electrospun fly ash/polyurethane fibers for absorption of volatile organic compounds from air. J Chem Eng. 2013;230:244-50.

44. Dehghan SF, Golbabaei F, Maddah B, et al. Optimization of electrospinning parameters for polyacrylonitrile-MgO nanofibers applied in air filtration. J Air Waste Manag Assoc. 2016;66(9): 912-21.

45. Moradi GR, Sadighzadeh A, Yarahmadi R, et al. Investigating the collection efficiency of ulpa filters for the removal of nano-sized aerosols. Iran Occupational Health. 2013:10(2):1-10.

46. Shou D, Fan J. Structural optimization of porous media for fast and controlled capillary flows. Physical Review E. 2015;91(5):053021.

47. Fisk WJ, Faulkner D. Performance and cost of particle air filtration technologies. Indoor Air. 2001;12:223-34.

48. Li P, Wang C, Zhang Y, et al. Air filtration in the free molecular flow regime: a review of high‐efficiency particulate air filters based on carbon nanotubes. Small. 2014;10(22):4543-61.

49. Kadam V, Kyratzis IL, Truong YB, et al. Air filter media functionalized with β‐Cyclodextrin for efficient adsorption of volatile organic compounds. J Appl Polym Sci. 2020;137(40): 49228.

50. Kadam V, Truong YB, Easton C, et al. Electrospun Polyacrylonitrile/β-Cyclodextrin composite membranes for simultaneous air filtration and adsorption of volatile organic compounds. ACS Appl Nano Mater. 2018;1(8):4268-77.

51. Ciobanu A, Landy D, Fourmentin S. Complexation efficiency of cyclodextrins for volatile flavor compounds. Int Food Res. 2013;53(1):110-4.

Type of Study: Original articles |

Subject:

Environmental Health, Sciences, and Engineering

Received: 2022/03/12 | Accepted: 2022/04/20 | Published: 2022/06/20

Received: 2022/03/12 | Accepted: 2022/04/20 | Published: 2022/06/20

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |